AFM blow inside electric type self-cleaning filter

Your current position:HomeProductAF Series Automatic Self-cleaning FilterAFM blow inside electric type self-cleaning filter

Tel:+86.21 51097921/51090930

Manager Li:13306264360

Technical Support:Mr. Feng 15216602964

Email:jci_sales@163.com

Factory address: 368 Qinggao Road, Fengxian District, Shanghai

Applicable fields: Raw water treatment, water treatment system, refrigeration system, steel, papermaking, mining, petrochemical industry, precision metal manufacturing, municipal facilities.

Applicable fields: Raw water treatment, water treatment system, refrigeration system, steel, papermaking, mining, petrochemical industry, precision metal manufacturing, municipal facilities, etc.

Applicable liquid types: Ground water, sea water, lake water, reservoir water, circulating cooling water, chilled water, spray water, heat exchange water, sealing water, bearing cooling water, oil well water injection, process circulating water, machining coolant, cleaning water Wait.

Cases

Brand Name: JCI

Model Number: AFB

Packing Details: Non-fumigation wooden box

Supply Ability: 100 Pieces per Month

Operating Mode: Automatic

Certification: ISO9001:2000

Filter Precision: ≥ 30μm

Applicable viscosity range:< 40cp

Housing Material: SS304/316L/2205/CS

Scraper Material: Nylon/Stainless steel

Design Temperature: < 260°C or customized

Design Pressure: 0.6-1.6Mpa or customized

Warranty: 1 year

Customer design: Acceptable

Supply Ability: 100 Pieces per Month

Packing Details: Non-fumigation wooden box

AFB electric scraper self-cleaning filter (abbreviated as AFB filter) is a new self-cleaning filter of Shanghai Jiucheng Company with independent intellectual property rights. It automatically removes particulate impurities on the inner surface of the filter element through mechanical means and can continuously filter on-line. AFB filter can quickly remove impurities from the surface of the filter screen, thereby effectively removing more impurities, suitable for filtering water and various low-viscosity liquids. The AFB filter is designed and manufactured in accordance with Shanghai Jiucheng's high-performance, high-quality, and high-reliability standards to achieve high quality.

The AFB filter always keeps the filter element clean regularly in a self-cleaning manner, and discharges waste liquid containing high concentration impurities, reducing material waste, and filtering water with poor water quality and low viscosity liquids have the advantage of significantly higher efficiency. With its significant technical advantages and low operating costs, AFB filters are gradually replacing traditional manual filters such as bag filters, basket filters, etc.

| Model No. | AFB Series | ||

| Applicable liquid | Water and viscous liquids(˂800,000cps); impurity level˂1,000ppm | ||

| Filter precision | 30-5,000μm | ||

| Design pressure | 1.0MPa(Higher pressure can be customized.) | ||

| Design temperature | 0-260°C(It depends on seals.) | ||

| Single filtering area | 0.14㎡-1.45㎡ | ||

| Cleaning Pressure Drop | 0.05MPa | ||

| DP controller | Differential pressure transmitter or differential pressure switch | ||

| Gear motor | Three-phase power, 380V, protection grade IP55; Turbine worm reducer | ||

| Connection Standard | Flange, HG20592-2009(Standard), HG20615-2009( ANSI B16.5 Compatible) | ||

| Filter elements | V-shaped wadge net/ sintered mesh | ||

| Filter element material | SS304/316L/2205 | ||

| Housing material | SS304/316L/2205/CS | ||

| Brush material | Nylon/stainless steel | ||

| Housing seal material | NBR Nitrile Rubber(Standard)/viton (FKM) fluoro rubber | ||

| Discharging valve | Pneumatic ball valve, protective grade IP65 | ||

| Facility supply | 380V AC, 0.4-0.6MPa Clean and dry compressed air | ||

Outline drawing and dimensions:

| ITEM NO. | Nominal diameter of inlet and outlet | DIMENTION | |||||

| H1 | H2 | H3 | H4 | D | L | ||

| AFB14 | DN32~DN50 | 500 | 270 | 100 | ≈950 | 273 | 450 |

| AFB28 | DN40~DN65 | 760 | 320 | 100 | ≈1270 | 273 | 480 |

| AFB42 | DN40~DN80 | 980 | 335 | 100 | ≈1500 | 273 | 500 |

| AFB77 | DN50~DN100 | 1190 | 430 | 100 | ≈2050 | 450 | 650 |

| AFB116 | DN50~DN125 | 1400 | 525 | 140 | ≈2150 | 550 | 800 |

| AFB145 | DN65~DN150 | 1650 | 540 | 143 | ≈2600 | 550 | 800 |

【Filtering status】

The liquid flows in from the inlet, and the strip-shaped scraper is close to the surface of the filter element. The liquid flows outward from the surface of the filter element through the filter. The impurities are trapped on the inner surface, and the liquid flows out from the outlet; as time goes by, the impurities gradually When the pressure increases, the pressure difference rises, and the filter screen is cleaned according to the set pressure difference or regularly.

【Cleaning state】

The motor drives the scraping brush to clean the filter screen in a horizontal rotation motion. When the scraping brush rotates, the impurities are removed by the brush and flow to the bottom of the filter, and the impurities with large specific gravity settle into the dirt collection chamber. Each cleaning consists of several strokes. After the surface of the filter is cleaned, the filtering capacity is restored. Normally filter during cleaning without interruption of flow.

【Sewage discharge state】

After multiple cleaning cycles, the impurities have accumulated to a sufficient amount, and the drain valve is opened regularly to discharge the waste liquid with high concentration of impurities. If necessary, it can also be recycled.

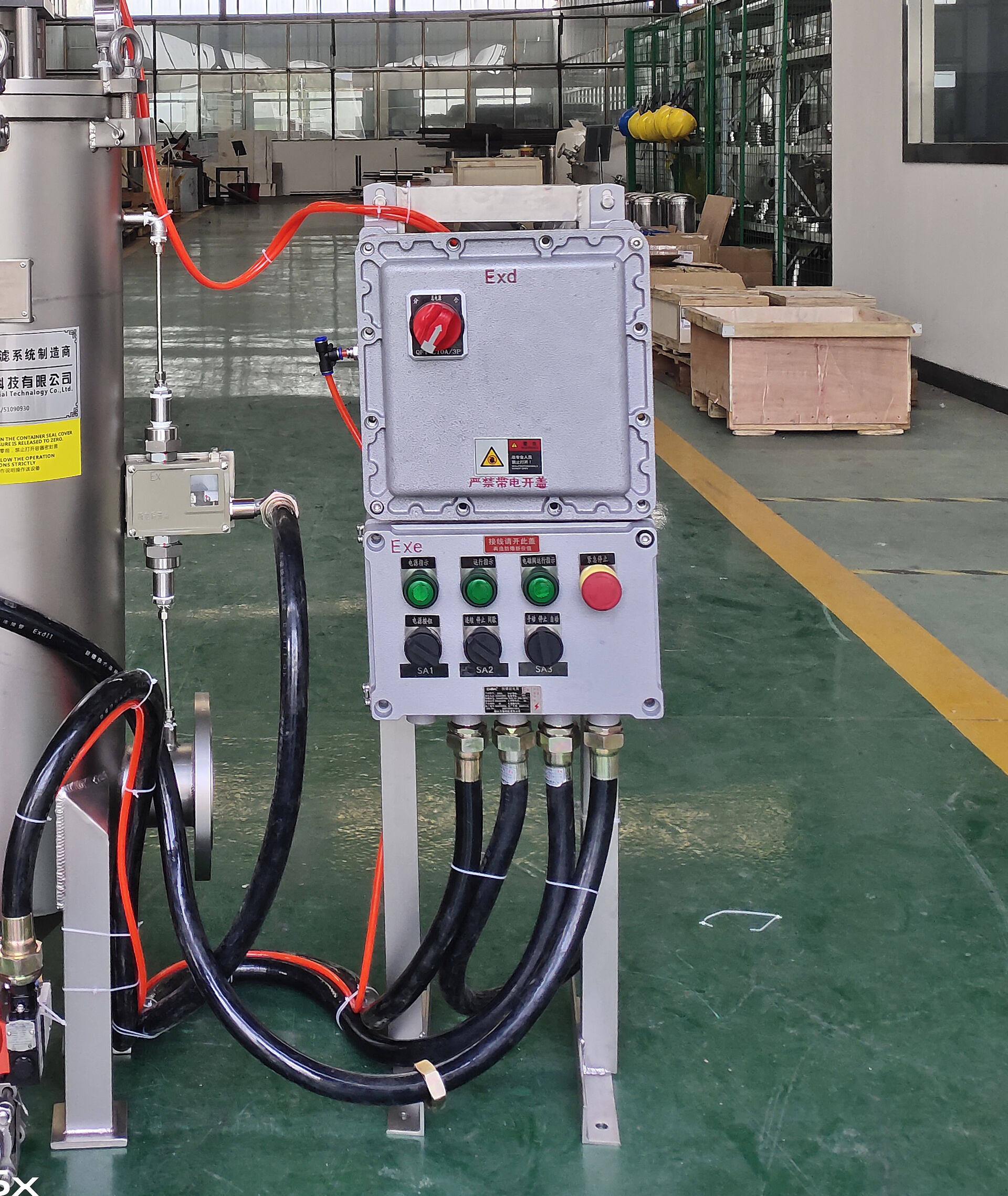

Automatic cleaning control system

AFB filter is equipped with an automatic cleaning control system, which integrates the parallel control function of differential pressure cleaning and timing cleaning, and can control the high-energy operation of the filter according to the working conditions. If necessary, DCS remote real-time monitoring can also be realized after customization. Differential pressure cleaning is suitable for most occasions and is an effective cleaning mode. The differential pressure reflects the accumulation of the filter cake on the inner surface of the filter or the clogging of the filter element. When the set pressure difference is reached, the self-cleaning action is started. Cleaning is recommended The differential pressure value is 0.1 MPa, which can be adjusted within the range of 0.01-0.1 MPa according to the working conditions. Timed cleaning can be set between 0-24 hours. For example, when the differential pressure mode fails, the time mode still works and can be used as terminal safety protection. The cleaning cycle setting should be close to the average cycle of the filter differential pressure cleaning mode. The automatic control system differential pressure transmitter has two forms of differential pressure switch and differential pressure transmitter. The transmitter can output real-time differential pressure value with high sensitivity and reliability, which is convenient for DCS remote real-time monitoring.

1. Horizontal rotary scraping, scraping off impurities directly, good at filtering low-viscosity liquids, removing particles and suspended impurities.

2. Simple structure, easy to disassemble and assemble. After removing the scraper, the filter can be easily taken out, and the inside is easy to clean.

3. Fully automatic operation, continuous online filtration, and stop the heavy filter replacement and cleaning work.

4. No disposable filtering consumables are generated, saving consumables costs and environmental protection costs.

5. The filtration pressure loss is extremely small, the flow rate is stable, energy consumption is saved, and the process is continuous and stable.

6. Airtight filtration to prevent leakage of hazardous materials, which is beneficial to safe production and employee health.

7. The discharged waste liquid has a high impurity concentration and can be recycled, reducing the loss of high-value materials.

8. A variety of control systems are optional, powerful, high-energy operation, high reliability.

9. Selected parts, high reliability, low operating cost.